In partnership with TriNav Marine Design , FFAW-Unifor are seeking an appropriate candidate to move forward with retrofitting a commercial inshore fishing vessel with a diesel electric hybrid propulsion system.

The survey for Expressions of Interest closed on January 31, 2024 and FFAW will be screening candidates with TriNav throughout February 2024. There will be a small number of candidates shortlisted in the screening process, and the candidate will be finalized following visits to the vessels, examination of compatible systems, and presentations from the supplier on the installation process. Once the candidate is finalized, the next step is to apply for funding to move forward – no financial contribution will be required from the enterprise owner for the retrofitting and equipment for the project. Once the retrofitting is completed, and outside of their fishing season, the candidate’s vessel will be used to demonstrate performance of the vessel with less reliance on diesel fuel to other enterprise owners around the province. This reporting will be the foundation for building a larger submission to federal government with other independent fisheries in Canada to put financial incentives, such as rebate programs, in place to help transition commercial fishing fleets.

To avert impacts of climate change, the Government of Canada has committed to achieving net-zero emissions by 2050. In alignment with this goal, FFAW and TriNav hope to achieve no less than a 25% savings in fuel/co2, but preferably 50% or more. This will increase the opportunity for accessing future funding and make the project more viable long term.

Inshore fish harvesters represented by FFAW-Unifor has previously partnered with the Canadian Centre for Fisheries Innovation (CCFI) to develop initiatives to increase fishing vessel energy efficiency through consultation and educational workshops, and this is a natural continuation of our industry demonstrating innovation.

BACKGROUND

In 2021, FFAW-Unifor undertook a Feasibility Study led by Dr. Sue Molloy of Glas Ocean and David Lea of CBCL Limited to examine the greenhouse gas (GHG) impacts of the fishery and the way forward towards an electric powered fishing fleet. The study also examined the benefits, challenges, and potential compromises that may be needed for such a transition.

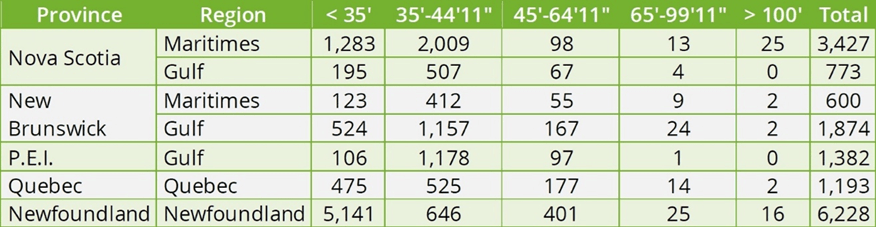

The inshore fishing fleet of Newfoundland and Labrador is much larger (6,228 total vessels) than any other Atlantic province and has a much greater percentage of small (<35’) fishing boats (82%) in its commercial fleet than any other province. Since vessels of this size are predominantly involved in day fishing, it is this class of vessel that is most suited to electrification due to its ability to recharge at dockside daily.

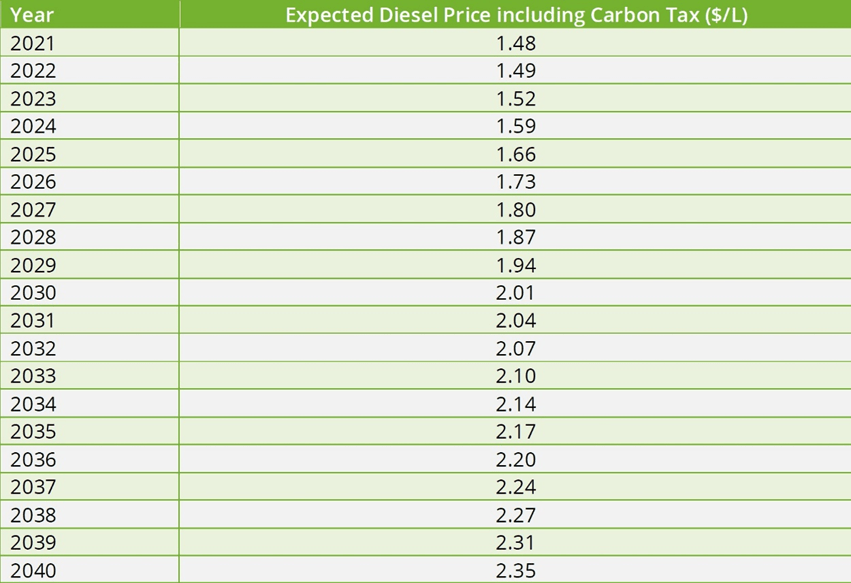

As we know all too well from 2023, fuel use is one of the costliest parts of a fishing trip and is dependent on vessel size, trip length and duration, speed, age of vessel and engine, weather conditions and other factors. Another consideration is the impact of the carbon tax, which commercial fish harvesters are exempt from now but will be subject to in near future. In fact, on page 34 of the Feasibility Study, the following table cited the expected future fuel costs per litre of diesel. As you can see, when the Study was prepared in 2021 it was predicted that diesel would be $1.52 per litre this year. Recessionary pressures and the Russian war on Ukraine have actually made the average price of diesel $1.80 per litre in 2023.

The increased efficiency of the electric motor when compared to the diesel and gasoline motors is an added benefit of electrification, together with reduced GHG, reduced exposure to fumes and oil spills, and decreased sound levels. Electric motors are upwards of 95% efficient whereas gasoline and diesel motors are between 20-30% efficient. Further, electric motors in the main areas of Newfoundland and Labrador fishing grounds would also have the added benefit of being connected to grid power almost exclusively by renewable energies (Muskrat Falls, etc.), further reducing their GHG emissions footprint. Those in communities with isolated grids would not reap this benefit but would still see a GHG emissions reduction when compared to the energy usage of a gasoline or diesel motor.

Fuel savings is based on the use of the battery. The diesel system uses 50% less fuel idling than going full speed which is a substantial amount of fuel to be used for warming up. Fuel prices will change over the next 20 years as carbon pricing is added, meaning that electrification of commercial vessels is aligned with government’s Greening Government Strategy of an 80% reduction in greenhouse gas emissions from federal government operations by 2050. Additionally, this means that the bottom line for enterprise owners will also have significant savings to operational costs!

The electrification of inshore fishing vessels holds the potential for meaningful environmental and economic benefit. As is the case with electric cars, greenhouse gas emissions are eliminated due to the lack of an internal combustion engine. The lack of required maintenance and obviously lesser fuel costs also contribute to a lower price of operation than many traditional boats. In a hybrid system, the diesel system can be used for the transitioning operations and the battery can be used for the low-power operations.

The more a system is used, the faster and better the payback of the system. Drivers such as CO2 reduction, ocean health, underwater radiated noise reduction and health and safety should also influence decisions to prioritize electrification of the fleet. It would be reasonable to place a value on the environmental and health cost of diesel operations to get a true accounting of the value of electric. For a fleet of 10 vessels operating 100 days per year, all-electric, we can expect a displacement of 500 tonnes of CO2 per year. Applying this to the entire Atlantic Canadian fleet of 15,000 boats in this size range, all-electric operations could displace as much as 750,000 tonnes of CO2 – An unmistakable win for Canada’s oceans and ocean economy!

Harvesters in Newfoundland and Labrador have identified finances as the main barrier to implementing more advanced technology. There are programs available from various levels of government for the green economy, including the possible claiming of carbon credits, however; the transition to low carbon solutions will require a more streamlined effort to provide accessible funding opportunities.

FFAW Contact: Courtney Langille, Government Relations – clangille@ffaw.ca

TriNav Contact: Rick Young, Naval Architect – ryoung@trinav.com

FREQUENTLY ASKED QUESTIONS

-

- Will the contract have a clause for removal if they decide to return to their previous diesel system? Visits to the vessels of shortlisted candidates, presentations from suppliers, and detailed consultations will be completed up front to reduce the likelihood of the owner not being happy with the system. The system chosen will not be a prototype. It will a proven should be a proven and accepted marine system, suitable for the vessel type and size. To enhance confidence, the chosen system will already proven product and the supplier will offer education in advance as well as good support after it is installed. If the system were to be removed, responsibility will lie with the vessel owner. Installation is forecasted to take 6-months beginning in the Fall to ensure that at-sea trials are completed before Spring. Removal of the system could take three to four months to remove and install a new propulsion system.

-

- What will be the implications for the harvesters’ boat insurance? Any modification to a fishing vessel of any size is required to be in compliance with the TC Small Fishing Vessel Regulations. If the vessel is >15GT then the modification is required to be inspected and approved by TC; so, a drawing and information will have to be submitted to TC for approval. The system supplier and installer should have acceptable liability insurance in place and warrant their products and work for at least one year, in keeping with industry standard. The installer should have ship repair insurance, but with that said, the vessel owner’s insurance company should not have any issue with insuring the modified vessel if all the noted requirements are in place. The vessel owner will likely have to increase his insured value to represent the increased value of his overall vessel due to the upgrade.

-

- Will the supplier of the equipment be the same as the installer? The supplier of the equipment may not be the same as the installer (ie. Samsons supplies the system, HGOE installs). Once the candidates are shortlisted and a suitable supplier is selected, the supplier will want to visit the vessels to ensure that the vessel is acceptable for their system equipment before finalizing their quote which will be a key part of the funding proposal.

-

- Where are we applying and is there a high chance of approval? At this stage, we have shortlisted the Atlantic Canada Opportunities Agency (ACOA) and the Atlantic Fisheries Fund (AFF) as primary funding channels for application, but we will also pursue funding opportunities that may be available through Innovation Canada and ZEV Project Funding. Given the nature of the project and the alignment with Canada’s goal of net-zero emissions by 2050, we feel like the funding opportunity is strong, but like any application process, there is no guarantee.

-

- Is there a preference to what type of boat will be accepted? Not specifically. Most vessels are designed with the fish hold aft and the engine room and wheelhouse forward. A newer, larger vessel with a sizable engine room will be preferred to provide necessary space for generator/batteries/cooling and fire fighting systems that will be required, without taking away from the current fish hold and deck space.

-

- Is fiberglass the only acceptable hull material for consideration? A newer vessel would likely make a better candidate due to the larger size of newer vessels. These vessels are most likely constructed of fiberglass. If any structural modifications are required during retrofit, fiberglass is easier to modify.

-

- Is there a size restriction? The project will be more suited to vessels in the 35’ to 49’ category due to space and safety requirements for the necessary equipment.

-

- Will this new system take up more space and remove some holding capacity from the fish hold? The intent is to design a system that will not take away from existing fish hold capacity but utilize current engine room space. This is one reason why a newer, larger (wide and deep) vessel is a preferred candidate.

-

- Are we only considering vessels that fish certain species? No, we are not screening on account of certain species, but the correlation to quota and the weight of landings which impacts the space/holding capacity as well as the power output for the system

-

- Is there a voyage restriction (a vessel that typically makes 5-7 day trips vs. inshore/ 1 day trips)? These details are being determined in conjunction with potential equipment suppliers, but it is more relevant to vessels making 1 to 3 day trips

-

- Would the homeport have to have a special charging station – much like electric vehicles? The vessel will be hybrid/diesel-electric, so the diesel internal combustion engine drives a generator to produce energy for batteries. Energy storage capabilities are in the form of a battery pack, hybrid control system, power transfer system and an energy storage system. The key element in hybrid type of power systems is how to store the energy safely and efficiently in conjunction with charging capability at port. The ability to charge at dockside during tie-up would be an asset and may be available through current shore power connections. Details are yet to be determined. The most available technology at present is batteries. The design and the capacity of an energy storage system will depend on how the system is to be used and this is why the specs noted in the survey are important to determine whether we prepared to meet additional power needs like refrigeration, etc.

-

- What is the timeline for the project? The project is currently in the information and data collection phase, and the approximated timeline will be adjusted as things move forward:

- February 2024 – Screening process; Candidates are shortlisted

- March 2024 – Visits to candidates’ vessels; Presentations on compatible systems by suppliers; Cost analysis

- April 2024 – Final candidate chosen and system selected; Funding breakdown determined

- May and June 2024 – Drafting, review, and refinement of funding proposals

- July 2024 – Funding proposals submitted (contingent on deadlines/funding periods)

- Fall 2024 – Funding secured, agreement(s) endorsed and funds dispersed; Retrofitting process begins in step with reporting requirements

- Spring 2025 – Retrofitting complete; At-sea trials with vessel owner

- Summer 2025 – Reporting and recording during fishing activity as per existing funding guidelines; Planning for ‘demo tour’ at key ports

- Fall 2025 – Fishing season ends; ‘Demo tour’ begins

- January 2026 – Building of larger federal proposal for retrofitting rebate begins

- What is the timeline for the project? The project is currently in the information and data collection phase, and the approximated timeline will be adjusted as things move forward: